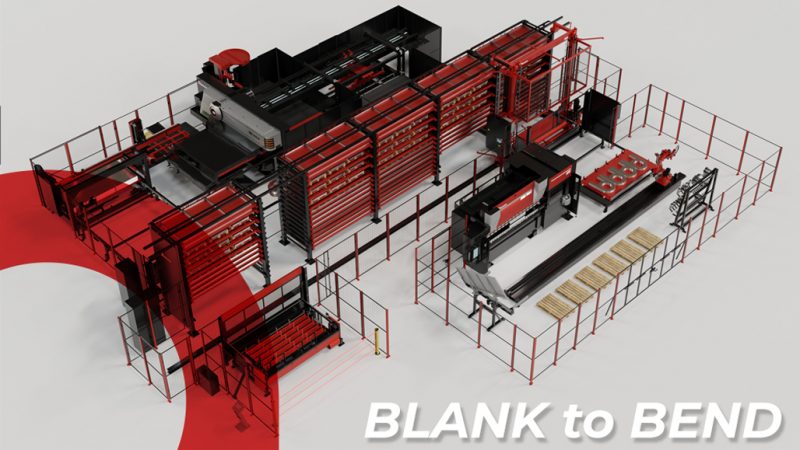

With AMADA’s new Blank-to-Bend concept, it is possible to perform cutting and bending in a single, highly-automated, end-to-end process. The element that binds these operations together is the AMADA CSII rack storage system.

AMADA has always supplied a wide range of outstanding systems for cutting blanks and bending them. With the new concept, AMADA is now linking together the production of the blanking with the automatic bending process. At the heart of the concept lies the AMADA CSII rack storage system. From here, the raw material enters an AMADA punching-, AMADA combination- and/or lasercuttingmachine which produces the cut blank. The storage system then feeds the materials to a bending cell equipped with robot and tool changer via a reliable, high-speed parts sorting solution with high positional accuracy. This then performs the fully automated final-bending operations to produce the finished component. An example of the Blank-to-Bend concept is provided by an AMADA EML-AJ punch-fiber laser combination machine, an AMADA CSII storage system and an AMADA HRB-ATC press brake on the other side of the rack.

Cumulative capacities

“The great advantage of the Blank-to-Bend-concept lies in the fact that all the cutting and bending operations, including materials handling, can be performed in a single highly-automated end-to-end system,” explains Axel Willuhn, Product Manager for Punching and Laser Technology at AMADA. “The Blank-to-Bend concept combines the high production capacity of each individual AMADA system to ensure the greatest possible productivity and efficiency.” The high staffing levels that were required in the past are no longer necessary and the risk of errors as well as damaged parts is reduced to an absolute minimum.

Low investment outlay

Compared to the cost of the machines, the financial outlay involved in implementing the Blank-to-Bend concept is very small. When implemented in an existing production environment, the costs amount to less than ten percent of the overall system investment. And for customers who are setting up a completely new system, the implementation of the Blank-to-Bend concept represents no more than two percent of the total costs. The key areas of focus during implementation are the configuration of the storage system and the implementation of the software which ensures the end-to-end connection between the systems.

Customer-specific design

The Blank-to-Bend concept is of particular interest to AMADA customers that already possess an AMADA CSII storage system and/or an AMADA punch-, combi- and/or lasercuttingmachine and are now planning to extend their processes to include bending. During implementation, all the customer-specific pre-requisites and requirements are analyzed in detail and taken into account during the design of the Blank-to-Bend solution. AMADA has already worked on similar projects with its customers in the past and these have formed the basis for the development of the new, standardized Blank-to-Bend concept.