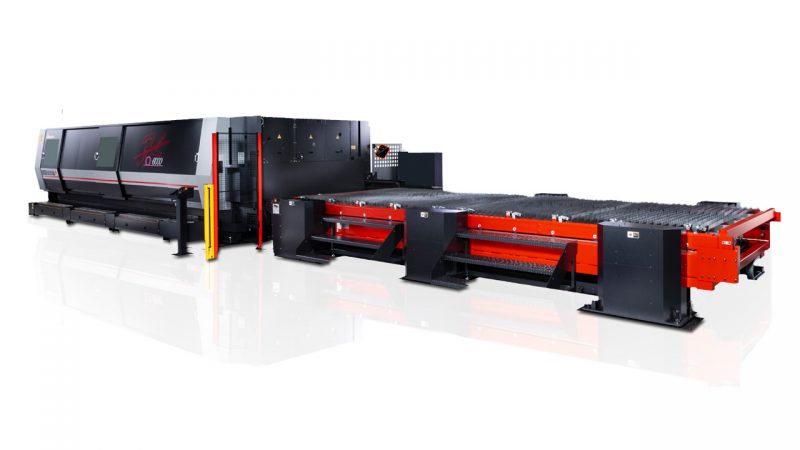

AMADA recently launched its ENSIS-6225AJ fibre laser cutting machine into the European market. With the ability to process a 6.2m x 2.5m sheet of material, the new machine is available in 6, 9 and 12kW variants, with all powers able to cut up to 25mm mild steel, stainless steel and aluminium. Many new and proven AMADA technologies are utilised to provide the highest levels of cutting performance to keep customers at the competitive edge.

Being able to process larger sheets, or multiple sheets in a large cutting area, leads to several benefits: More efficient material utilisation and higher production flexibility. Previously, AMADA’s ENSIS fibre lasers were available in 3 x 1.5 metre and 4 x 2 metre variants. Now, the series has been expanded to incorporate 6.2 x 2.5 metre capabilities.

Utilising AMADA’s proven Variable Beam Control technology, first released in 2014, the ENSIS-6225AJ automatically adapts the laser beam mode (not just the focal position and spot size) to each material and thickness combination. This technology also allows the beam mode to be changed between the pierce and the cut, to provide a high power density beam shape for high speed piercing, then instantly changing to the ideal beam shape to provide high speed, high quality cutting. It also means that a single lens can be used to process all materials and thicknesses.

Several new Laser Integration System features have also been added to the ENSIS-6225AJ, as first released on the REGIUS-AJ, full linear drive laser in 2020. These provide more autonomous functionality, rather than relying on the operator to carry out certain checks.

The i-Nozzle Checker automatically checks the nozzle condition and changes it in conjunction with the standard 16 station nozzle changer if damage is detected, thereby removing any subjective operator decision. This system also incorporates automatic laser beam to nozzle alignment, significantly reducing start-up times and processing issues. The i-Process Monitoring system constantly monitors the cutting and piercing processes and takes remedial action if required, in order to keep the machine producing parts. The cutting lens protection glass is monitored by the i-Optics Sensor, which alerts the operator if the protection glass needs to be replaced, to avoid potential stoppages.

Several other AMADA technologies are also supplied as standard on the ENSIS-6225AJ. Firstly, AMADA’s original Water Assisted Cutting System (WACS), used for processing thick mild steel, has been upgraded to allow 2 different levels of assistance, depending on the part geometry.

WACS II can provide greater material utilisation by allowing parts to be nested closer together, improved quality and the ability to process very thin wall thicknesses (3mm in a 25mm thick mild steel part, for example) can be realised.

Secondly, AMADA’s Clean Fast Cut (CFC) technology allows nitrogen cutting of mild steel and stainless steel at cutting speeds up to 90% faster than conventional nitrogen processing with assist gas consumption reductions of up to 70% per metre. These factors provide lower cost-per-part manufacture.

Compressed air cutting is another standard feature on all AMADA lasers, enabling many materials and thicknesses to be processed with much reduced costs compared to nitrogen cutting. Generally, cutting speeds are the same as with nitrogen and can even result in slightly better cutting quality for mid thick mild steel.

Finally, the Deep Etch function allows part traceability through the entire manufacturing process, even after painting, coating or galvanising, and is achieved in a single pass of the laser beam.

With regard to easy operation, AMADA’s AMNC 3i control has a smartphone-like interface with a large touch screen and many one-touch operations to simplify operator tasks. A notable new feature provides a boost for remnant cutting thanks to the optional i-Camera Assisted System (i-CAS). If a new part requires cutting to replace one that has been damaged in assembly, for example, the machine’s i-CAS camera can display the selected remnant on the AMNC 3i control. The part is then chosen from the library and can be positioned, rotated, copied and so on, before remnant cutting commences. Remnants can be placed anywhere on the bed.

Further standard features of the ENSIS-6225AJ are 3 Y axis conveyors, which remove the scrap to the long side of the machine, allowing quick and convenient scrap removal; a processing point camera making it very easy for the operator to see exactly what is happening at the cutting area (often a difficult task on a large bed laser) and V-Monitor, which consists of 2 cameras (1 in the cabin and 1 over the pallet changer) that allow remote viewing of the machine condition as well as recording HD video in the event of an issue, allowing remote diagnostics to be performed.

AMADA’s V-factory system is available for the ENSIS-6225AJ, allowing machine data such as production status, alarm information and processing history to be monitored anytime, anywhere on a smart device.

More Informations: