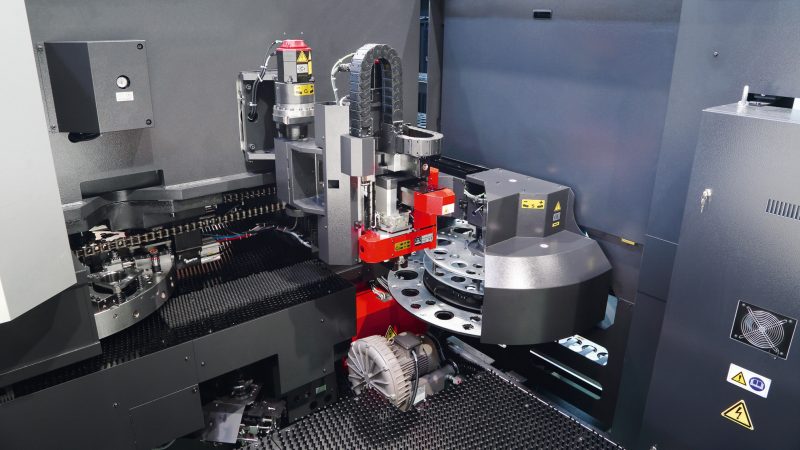

Have you ever thought about a punching machine with an automatic tool changer?

Our EM series with automatic tool changer system convinces with low down times, low waste and high process reliability.

To ensure optimized management of the many different tools, AMADA has made use of a proven innovation: ID Tooling is a digital tool recognition system that is controlled by QR codes present on the tools. As early as in the setup turret, the system is able to recognize the installation state of the tools. It verifies their status in terms of size, shape, angle and stroke rate. ID Tooling is also responsible for pairing the upper and lower tools and ensuring that they match correctly. If necessary, the system switches automatically to a replacement tool.

When used in combination with the ID-TOGU tool grinding machine, the EM-3612 ZRB becomes even more productive than before. After each regrinding operation, the up-to-date tool data is determined and made available to the system. When the tool is used again after grinding, the punching system detects its status, knows exactly how much has been ground away and how the tool has to be controlled. The time-intensive manual transfer of the new tool dimensions to the system controller is no longer necessary.

[su_custom_gallery source=”media:1000,1001,1002,1003,1004,1007,1008,1009″ limit=”50″ link=”lightbox” width=”220″ height=”130″]